Description

The screw press machine dehydrates materials by squeezing them physically. Materials enter, get squeezed by a spiral auger, and release water through a screen. This method is cost-effective for various materials, without needing heat or ventilation.

Equipment Showcase

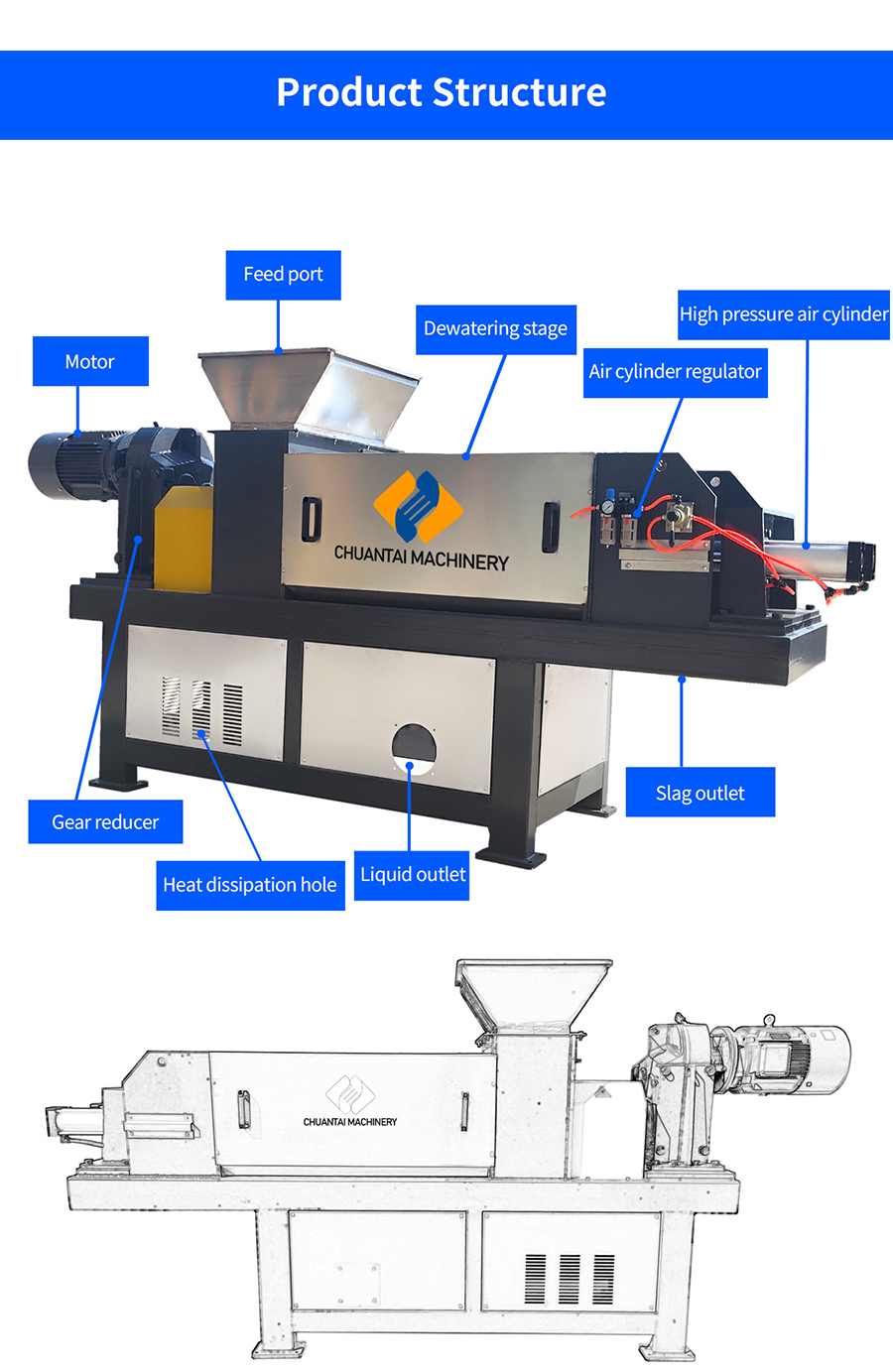

Working Principle

The spiral press dehydrator undergoes a two-stage dehydration process. In the first stage, utilizing the spiral auger with transmission, compression, and discharge sections, material entry is smooth. The dehydration section reduces transfer space, applying pressure to decrease material volume and extract water. In the second stage, a blocking device is used. As materials enter the discharge section, axial thrust pushes them out, and the pressurized hydraulic blocking device provides counterforce for extrusion pressure in the second-stage dehydration.

Advantages

◆Low-cost operation: The spiral press dehydrator utilizes the physical extrusion principle, requiring no additional heat source and resulting in lower energy consumption.

◆High processing capacity: Through a special process, the spiral auger enhances axial thrust, resolving operational issues and significantly increasing processing capacity per unit of time.

◆Low residual moisture: Engineers customize parameters based on material characteristics, reducing extruded material moisture content and enhancing physical pressing effectiveness.

◆Wear and corrosion resistance: Key components are coated for wear resistance, and the spiral auger blades are surfaced with alloy tips. Core components are made of 304 stainless steel, extending the equipment lifespan.

We have been in this industry for over a decade.Please feel free to get in touch with us anytime,we are dedicated to providing the best service and top-quality equipment to meet your needs.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China

Copyright © 2022-2024 Chuantai Machinery, INC. All Rights Reserved.

sitemap Screw Press Dewatering Machine