What are the working steps of fruit and vegetable waste treatment equipment?

1、 Receive

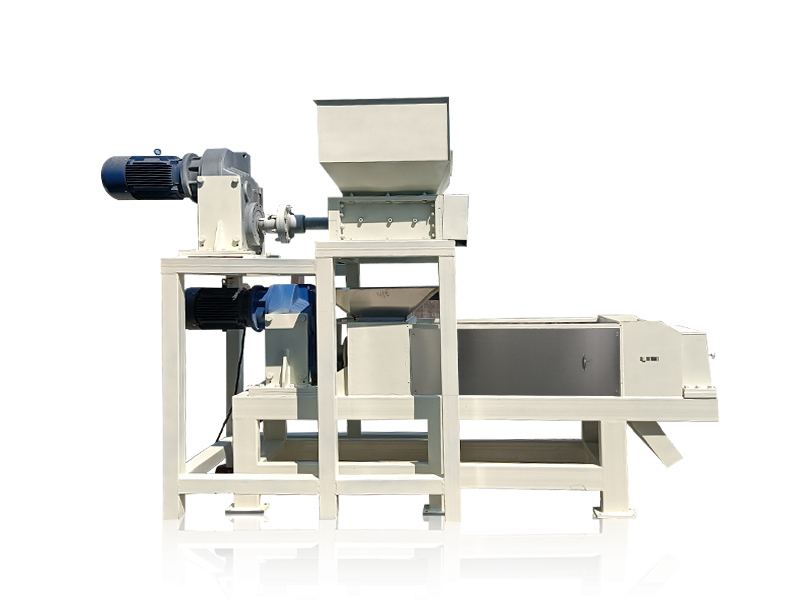

Fruit and vegetable waste is manually sorted, and the sorted fruit and vegetable waste is poured into the equipment through the automatic lifting device of the fruit and vegetable waste treatment equipment for processing.

2、 Preprocessing

After the fruit and vegetable waste enters the equipment, it is crushed by a crusher. After crushing, the material enters the extrusion dewatering machine. After being dehydrated by the squeezing dehydrator, the water content drops below and is then transferred to the biological fermentation warehouse for fermentation treatment.

3、 Biological fermentation

The squeezed fruit and vegetable waste enters the fermentation warehouse for alcoholization. In the biological fermentation stage, because fruit and vegetable wastes contain a large number of unstable macromolecular organic substances, including protein, starch, cellulose, heteropolysaccharide, fat, etc., they can be degraded by microorganisms into stable and simple inorganic substances and Humus. The aerobic microorganisms in the degradation tank rapidly degrade fruit and vegetable waste through high temperature, and the easily degradable parts of fruit and vegetable waste can be treated within hours.

4、 Biological deodorization

The exhaust gas collected in the alcohol device enters the deodorization device through the air outlet. The exhaust gas first enters the pre washing tower from the bottom of the reactor, which can remove dust from the odor, avoid blocking the biological deodorization system, and also cool down and partially dehydrate. The waste gas treated by the pre washing tower enters the packing area, and the pollutants in the odor are intercepted and decomposed by the biological packing. The upper part of the packing is sprinkled with water intermittently to ensure a certain humidity in the packing area, providing favorable conditions for biological metabolism and reproduction. The exhaust gas meets the emission standards through biological deodorization devices.

5、 Sewage treatment

The wastewater discharged during the squeezing dehydration process is first discharged into the water collection well through a sewage pipe. The water collection well is lifted to the water collection tank by a lift pump to buffer and regulate the discharge of wastewater flow, stabilize the regulation of water volume and quality, and ensure the continuous operation of subsequent treatment equipment. The waste water is removed from the large particle impurities through the centrifuge and discharged into the intermediate tank. Then it is sent to the oil separation sedimentation tank through the lift pump for secondary treatment, and then discharged into the Cesspit. The uniform wastewater with stable indicators is discharged through the Cesspit.

******Before using fruit and vegetable waste treatment equipment, the following preparations should be made:

1. Before using the fruit and vegetable waste treatment system, it is necessary to use cleaning solution to clean the parts of the mechanical equipment that come into contact with the raw materials.

2. Before starting the fruit and vegetable waste treatment equipment, it is necessary to check whether all parts are flexible, intact, without impact noise, and whether the fasteners are firm and reliable. Only after all electrical components are normal can they be used.

3. When using fruit and vegetable waste treatment equipment for *****, it is necessary to minimize excessive working pressure as much as possible, otherwise it may cause common problems such as sudden shutdown of the fruit and vegetable waste treatment equipment or rupture of the sieve barrel.

4. After ****** use, the fruit and vegetable waste treatment equipment must be carefully cleaned to not only facilitate the next use, but also to avoid damage to the system caused by residues.

5. After the initial treatment of the fruit and vegetable waste treatment system, if there is a small amount of vegetable gluten and residue in the sieve ring, it will not spoil and will not be affected for the next treatment. When investing a large amount of hard waste, it should be dispersed. When there is a lot of vegetable gluten waste treatment, the mixed input treatment has a better effect.

TEL:+1(626)776-8119

TEL:+1(626)776-8119

WeChat:gongchris1111

WeChat:gongchris1111

ADD:17559 Rowland Steven, Ste B, City of Industry, CA 91748

ADD:17559 Rowland Steven, Ste B, City of Industry, CA 91748