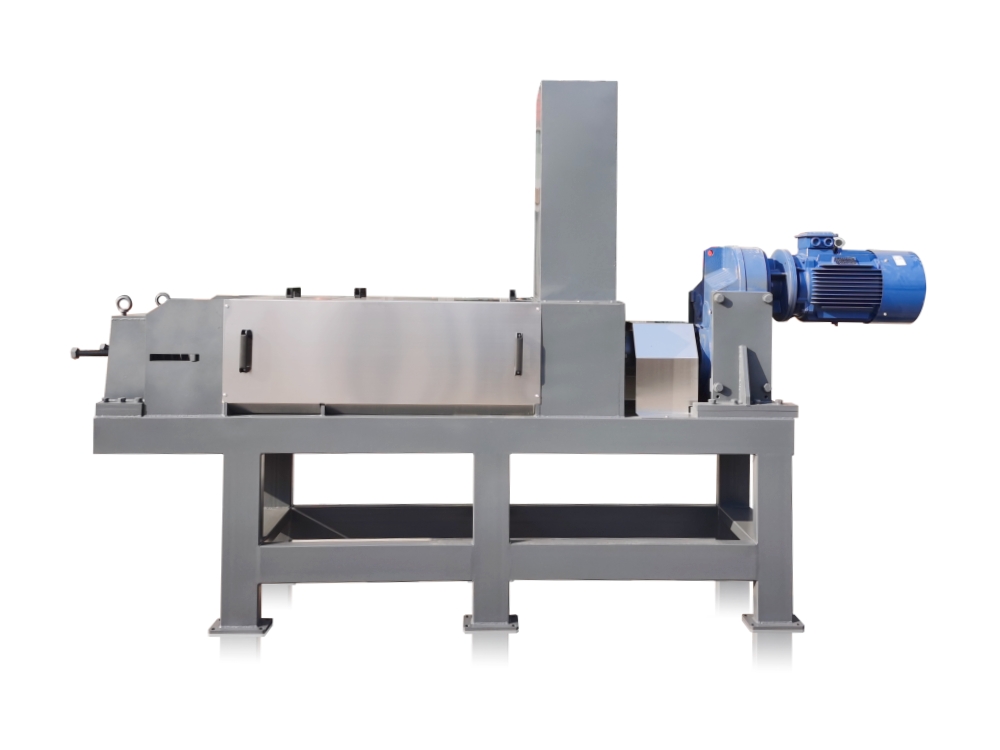

Working principle of solid-liquid separator:

The poultry manure solid-liquid separator transports the manure to the main machine through a non-clogging slurry pump, and pushes the manure to the front of the main machine through the extrusion screw auger. Under the influence of the side pressure belt filter, the moisture of the material is squeezed out of the mesh screen and flows out of the drain pipe. The separator continuously pushes the manure to the front of the main machine, and the pressure in front of the main machine is constantly increasing. When it reaches a certain level, it will open the discharge port and squeeze out the extrusion port to achieve the purpose of extrusion. Through the balance block under the main unit, the working efficiency and water content can be adjusted according to the needs of customers.

What are the advantages of a solid-liquid separator?

The solid-liquid separator is a device specially used for the dry and wet partition of sticky and wet objects, especially the dry and wet partition of livestock and poultry manure.

The livestock and poultry manure particles separated by the solid-liquid separator can be used as fertilizer or river shrimp bait after processing, and it is a very good manure recycling equipment

Green and environmental protection, no addition of separation. The solid-liquid separator is small in size, low in speed, and easy to install and maintain. There is no need to add any coagulant for dry and wet partitioning of manure.

1. The solid-liquid separator can be widely used for the separation of high-concentration organic sewage such as chicken, cattle, horses, animal manure, paper paddle, wine tank, residue, starch residue, sauce residue, and slaughterhouse.

2. The slag-liquid separation speed of the solid-liquid separator is fast, and the water content of the feces and slag after separation is between 40% and 65%, and the slag output and water content can be adjusted. It can be used for feed with different ingredients (such as grass feed), which is convenient for transportation, and its solid particles and raw materials suitable for fish feed organic fertilizer.

3. The solid-liquid separator has strong decontamination ability, no clogging, and easy to clean. The water-solid content, chemical aerobic content, and nitrogen and phosphorus removal rate of the treated excrement and urine can be between 70-95%.

4. The screen and Jiaolong of the solid-liquid separator are made of nickel alloy steel and high-toughness carbon steel, which is corrosion-resistant, high in strength and long in service life.

5. Strong power and high separation efficiency. The solid-liquid separator adopts an all-copper high-power motor, which has strong and durable power and strong working ability.

6. The solid-liquid separator has high degree of automation, low power consumption and low price. The operation is simple, just press the start stop button to operate.

7. During normal use, clean the screen every five months. When cleaning, first take out the discharge port bolt. Then remove the screen and clean the blockage with clean water.

8. Protect the environment and prevent pollution. The solid-liquid separator is specially used for the dry and wet partition of poultry manure in the breeding factory, so as to prevent the peculiar smell and waste water loss generated during the drying process of the manure in the farm, and pollute the environment.

The solid-liquid separator can reduce the concentration of suspended solids in water and reduce the processing load of subsequent processes. It is also used for solid-liquid separation and recovery of useful substances in industrial production. It is a good equipment for filtering or recovering suspended solids, suspended solids, sediments and other solid or colloidal substances. The solid-liquid separator is used to treat small industrial wastewater such as papermaking, slaughtering, leather, sugar, wine, food industry, textile, printing and dyeing, petrochemical, etc., and remove solid substances such as suspended solids, suspended solids, and sediments.

TEL:+1(626)776-8119

TEL:+1(626)776-8119

WeChat:gongchris1111

WeChat:gongchris1111

ADD:17559 Rowland Steven, Ste B, City of Industry, CA 91748

ADD:17559 Rowland Steven, Ste B, City of Industry, CA 91748