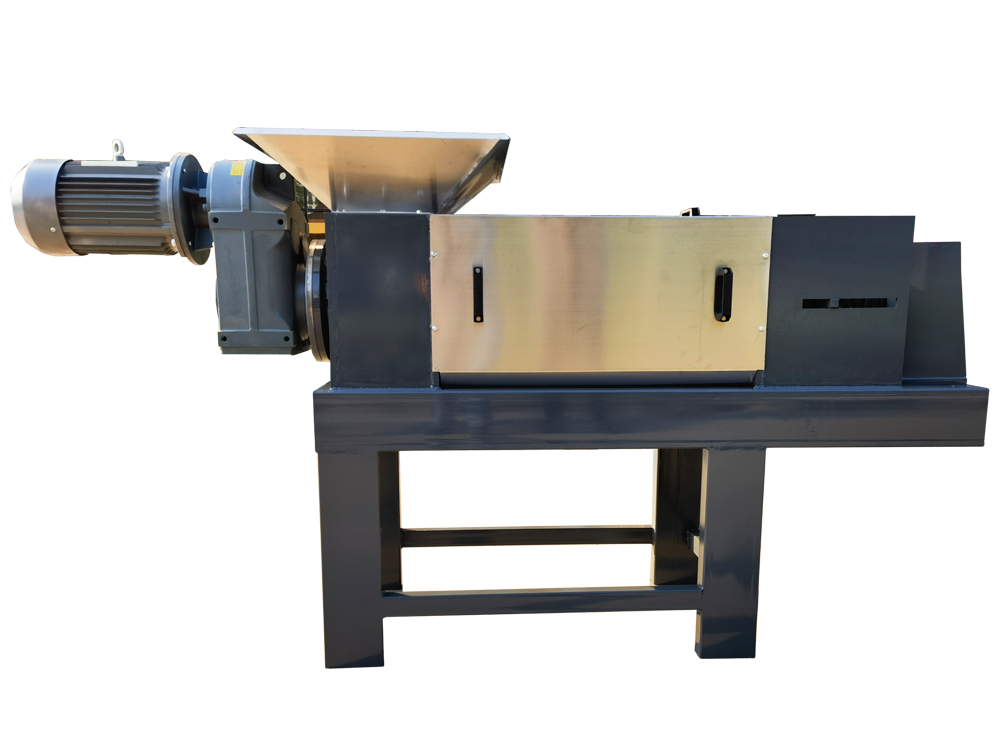

Dewatering screw presses play a crucial role in various industries by efficiently removing moisture from sludge and other materials. The pricing of these machines can vary significantly, influenced by several factors that manufacturers and buyers should consider. In this article, we will explore the key elements that impact the pricing of dewatering screw presses machines.

Capacity and Throughput:

One of the primary factors affecting the price of dewatering screw presses is their capacity and throughput capabilities. Higher-capacity machines designed to handle larger volumes of material generally come with a higher price tag. Manufacturers often offer a range of machine sizes to cater to different application needs, with each size having its associated cost.

Material and Build Quality:

The construction materials and build quality of a dewatering screw press significantly influence its price. Machines constructed from durable, corrosion-resistant materials tend to be more expensive. High-quality builds ensure a longer lifespan, reduced maintenance costs, and better overall performance, justifying a higher initial investment.

Automation and Control Systems:

The level of automation and sophistication in the control systems can impact the cost of dewatering screw presses. Machines equipped with advanced automation features, such as PLC (Programmable Logic Controller) systems and user-friendly interfaces, may be priced higher than those with basic manual controls.

Energy Efficiency:

Energy consumption is a critical consideration for many industries. Dewatering screw presses that incorporate energy-efficient technologies, such as variable frequency drives (VFDs) and efficient motor systems, may have a higher upfront cost but can result in long-term cost savings on energy bills.

Brand Reputation and Service Support:

The reputation of the manufacturer and the availability of reliable after-sales service can impact the pricing of dewatering screw presses. Established brands with a history of producing high-quality equipment and providing excellent customer support may command higher prices due to the perceived value and trust associated with their products.

Customization and Special Features:

Customization options and additional features tailored to specific industry requirements can affect the overall cost of dewatering screw presses. Buyers looking for specialized functionalities or unique adaptations to their processes should be prepared for potentially higher prices associated with customization.

Market Conditions and Competition:

External market factors and competition within the industry play a role in determining pricing. A competitive market may lead manufacturers to offer more competitive prices, while factors such as raw material costs and economic conditions can also influence the final price of these machines.

Conclusion:

Understanding the various factors influencing the pricing of dewatering screw presses machines is crucial for both manufacturers and buyers. By considering capacity, material quality, automation, energy efficiency, brand reputation, customization, and market conditions, stakeholders can make informed decisions that align with their specific needs and budget constraints.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China

Copyright © 2022-2024 Chuantai Machinery, INC. All Rights Reserved.

sitemap Screw Press Dewatering Machine