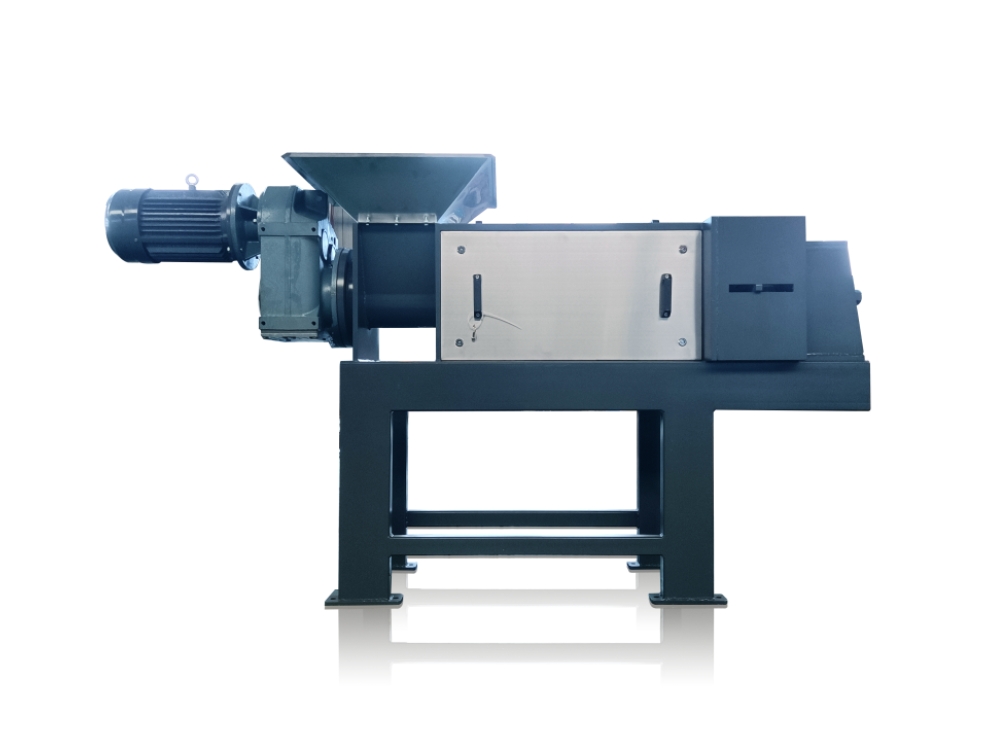

A screw press machine separator is a mechanical device designed for the separation of materials using the principle of a screw press. This innovative machine is widely utilized in various industries for the efficient separation of liquids and solids. Understanding the structural components of a screw press machine separator is essential for comprehending its functioning. The following is an overview of the key structural elements of this device:

Hopper:

The hopper is the initial component where the mixture of materials to be separated is introduced into the machine. It provides a controlled entry point for the raw material, ensuring a uniform and consistent flow into the screw press.

Screw Conveyor:

The heart of the machine is the screw conveyor, also known as the auger. This helical screw is responsible for conveying the material along its axis. As the screw rotates, it pushes the material forward, exerting pressure and facilitating the separation process.

Press Zone:

The press zone is a critical area where the actual separation occurs. It is characterized by increasing pressure along the length of the screw, which results in the compression and dewatering of the material. The design of the press zone is crucial for achieving the desired level of separation efficiency.

Screen or Perforated Cylinder:

Positioned within the press zone, a screen or perforated cylinder plays a pivotal role in separating liquids from solids. The choice of screen design and perforation size depends on the specific characteristics of the materials being processed.

Drive System:

The drive system is responsible for powering the screw conveyor. Typically, an electric motor provides the necessary rotational force to drive the screw. The drive system must be robust and capable of adjusting the rotational speed to accommodate different materials and separation requirements.

Frame and Housing:

The entire assembly is supported by a sturdy frame and enclosed within a housing. The frame provides structural support, while the housing contains the process and prevents any spillage. The design of the frame and housing is crucial for the overall stability and safety of the machine.

Discharge Chute:

Once the separation process is complete, the separated materials are discharged through a chute. The design of the discharge chute ensures a controlled and directed flow of the separated components for further processing or collection.

Understanding the interplay of these structural components is essential for optimizing the performance of a screw press machine separator. The versatility of this technology makes it a valuable asset in various industries, including wastewater treatment, food processing, and mining, among others.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China

Copyright © 2022-2024 Chuantai Machinery, INC. All Rights Reserved.

sitemap Screw Press Dewatering Machine