The benefits of dehydrating abattoir waste.

◆Efficient Dehydration: The spiral press machine, utilizing its spiral auger design, effectively dehydrates slaughterhouse waste through continuous mechanical pressing. This efficient process helps remove moisture rapidly, enhancing dehydration effectiveness.

◆Reduced Energy Consumption: In comparison to traditional methods like heat-based drying, the spiral press machine employs mechanical squeezing, eliminating the need for additional heat sources. This results in reduced energy consumption, making the dehydration process more economically efficient.

◆Preservation of Nutrients: The mechanical squeezing method is relatively gentle, helping to preserve essential nutrients and components present in slaughterhouse waste. This ensures that the final product retains its nutritional value.

Application

| Waste Reduction |

Kitchen Waste,Vegetable Waste,Fruit Waste,Plastic Waste,Fungus Residue, Cassava Residue,Coffee Grounds,Chemical Industry Waste,Slaughterhouse Waste,Charcoal,Beer Lees,Baijiu Lees,Activated Carbon,Chicken/Duck/Goose Feathers,Fish,Shrimp. |

|||

| Fiber Dehydration | Pulp,Wood Pulp,Bamboo Pulp,Sawdust, Pasture,Corn Stalks,Rice Straw,Wheat Straw,Sugarcane. | |||

| Ingredient Extraction | Hemp,Stevia,Mixed Medicine Residue,Tea Residue,Xylitol,Honeysuckle,Malt,Burdock,Tangerine Peel. | |||

| Fruit Juice Extraction | Apple,Pear,Lemon,Orange,Monk Fruit,Mango,Coconut,Papaya,Pineapple,Grape. | |||

| Vegetable Juice Extraction | Cabbage,Onion,Ginger,Celery,Tomato,Garlic,Beetroot,Carrot,Radish. | |||

| Livestock Farm | Cow Dung | |||

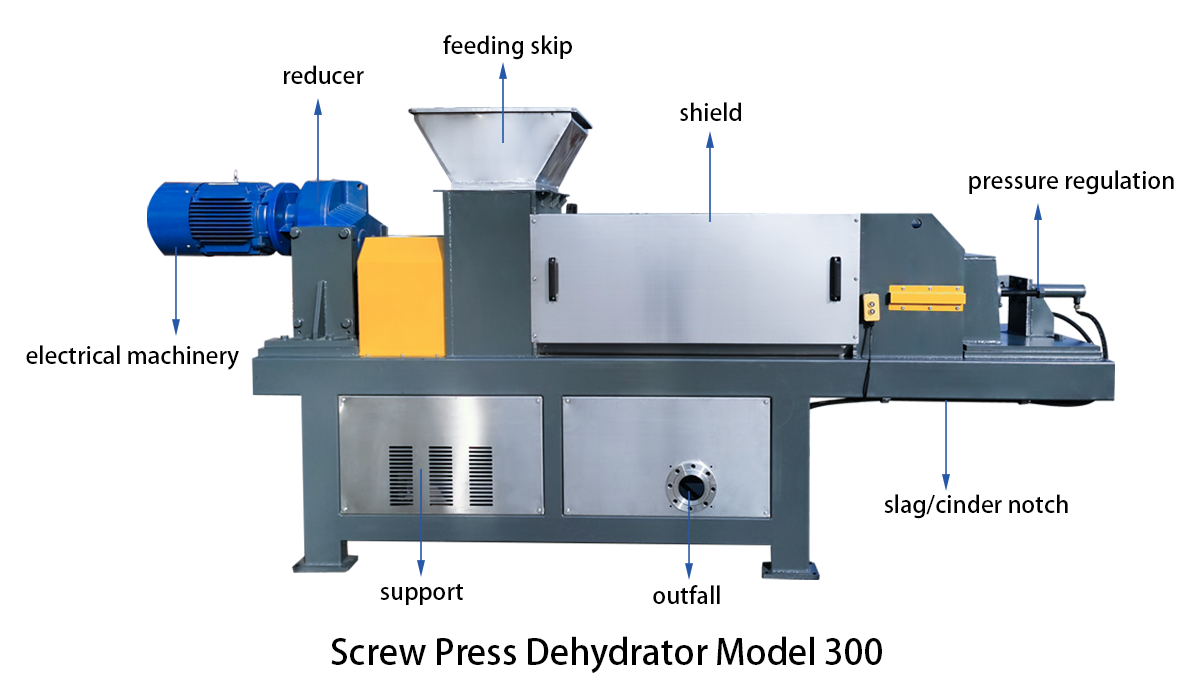

Structural Diagram

Parameters

| Model | Motor Power | Weight | Processing Capacity | Screw Diameter | Dimension (mm) |

| CT-200 |

7.5kw |

650kg |

2-5m³/h | 200mm | 2586*770*1400 |

| CT-300 |

18.5kw |

1500kg |

5-10m³/h | 300mm |

4142*890*1946 |

| CT-400 |

22kw |

3500kg |

10-15m³/h | 400mm |

4500*1000*2003 |

| CT-600 |

75kw |

7500kg |

20-30m³/h | 60mm |

6600*1300*2500 |

Advantages

◆Low-cost operation: The spiral press dehydrator utilizes the physical extrusion principle, requiring no additional heat source and resulting in lower energy consumption.

◆High processing capacity: Through a special process, the spiral auger enhances axial thrust, resolving operational issues and significantly increasing processing capacity per unit of time.

◆Low residual moisture: Engineers customize parameters based on material characteristics, reducing extruded material moisture content and enhancing physical pressing effectiveness.

◆Wear and corrosion resistance: Key components are coated for wear resistance, and the spiral auger blades are surfaced with alloy tips. Core components are made of 304 stainless steel, extending the equipment lifespan.

Production Site

Shipping Site

Contact Us

We have been in this industry for over a decade.Please feel free to get in touch with us anytime,we are dedicated to providing the best service and top-quality equipment to meet your needs.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China

Copyright © 2022-2024 Chuantai Machinery, INC. All Rights Reserved.

sitemap Screw Press Dewatering Machine