What are the precautions when using the screw press?

1. Under normal circumstances, adjust the feeding task of the screw press and check the whole equipment before each shift. The mechanical clamping of transmission system components and reducer requires sufficient lubricating oil; The hydraulic system clamps and checks the oil storage capacity of the vehicle oil tank and the working pressure of the hydraulic system.

2. It is forbidden to start the task of the screw press when the number of filter plates is less than the specified number, so as not to damage the mechanical parts. Check the arrangement of filter plates before feeding. The filter cloth shall not expand to avoid a large amount of water leakage; After unloading, the filter plates must be tightly clamped and neatly arranged.

3. The screw press can only clamp the filter plate for pressure screening. The filtration system and ambient temperature shall be within the specified range. High filtration system will cause water leakage. When the screening environment temperature is too high, the plastic product filter plate is easy to deform, and the solution concentration value should be evenly distributed when feeding.

4. The selection of filter cloth must meet the screening technical standards of filter element. The new filter cloth shall be shrunk before manufacturing, and the punching diameter shall be smaller than the filter plate diameter. When the filter plate of supporting facilities is installed, the holes shall be relatively concentric with the plate holes, and the feed hole shall be close to the material layer.

5. The screw press is turbid in the initial filter of the filter, and a layer of slurry on the filter cloth will become clear. If the filtrate is always turbid or mixed, the filter cloth may be damaged or the error between the cloth hole and the plate hole may be caused. At this time, close the valve or feed and replace the filter cloth.

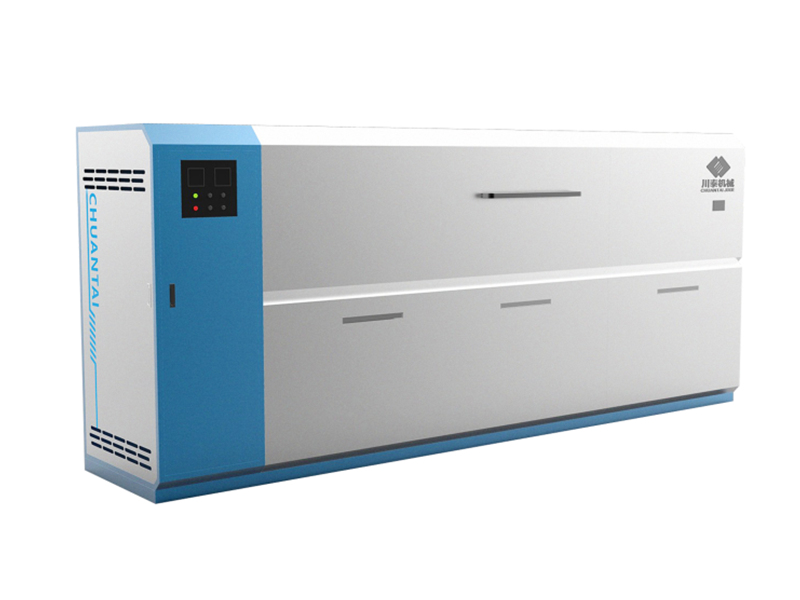

The screw press can be divided into regions and main features:

In terms of regional planning, the screw press can be divided into drainage pipeline area, feeding area, screw transportation area and feeding area.

(1) Due to the use of screw shaft extrusion, the total contact area with materials is small, and the sliding friction is small, which can reasonably improve the extrusion molding rate of the extruder, and prevent blocking and winding.

(2) The screw press is made of stainless steel plate with high compressive strength, good corrosion resistance and long service life.

(3) The drive equipment of the press adopts the method of shaft installation and immediate drive, and the mechanical equipment operates stably with low energy consumption. In addition, except for the inlet and outlet, others are sealed structures, which can be used for * * cleaning.

(4) The inlet and outlet of the screw press are equipped with elastic yellow baffles, which can adjust the extrusion working pressure to control the drying rate of the mechanical equipment.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China